In the world of industrial materials, few substances are as versatile and widely used as quicklime. Known scientifically as calcium oxide (CaO), quicklime is a key ingredient in many industrial processes, from steel manufacturing to environmental management. This comprehensive guide delves into the myriad uses of quicklime, its benefits, and the production processes that bring this essential material to market.

What is Quicklime?

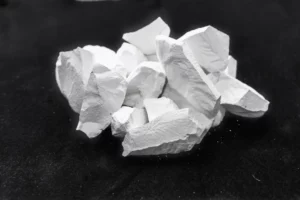

Quicklime, or calcium oxide, is a white, caustic, alkaline substance obtained by heating limestone (calcium carbonate) in a process known as calcination. This process involves heating the limestone to temperatures above 825°C, resulting in the decomposition of the mineral into calcium oxide and carbon dioxide. Quicklime is highly reactive and must be handled with care.

Uses of Quicklime

1. Steel Manufacturing

One of the primary uses of quicklime is in the steel industry. Here, quicklime acts as a flux, which removes impurities such as sulfur, silica, and phosphorus from the ore. The addition of quicklime in the steelmaking process improves the quality and durability of the final product, making it an indispensable material in this industry.

2. Environmental Management

Quicklime plays a crucial role in environmental applications. It is used to treat wastewater, neutralizing acidic substances and removing impurities. Additionally, quicklime is employed in the treatment of drinking water, where it helps to remove contaminants and improve water quality.

3. Construction and Building Materials

In the construction industry, quicklime is used to produce a variety of building materials. When mixed with water, quicklime forms calcium hydroxide, also known as slaked lime, which is used in mortar and plaster. Quicklime is also used to stabilize soil for road construction and to create lime-based cements.

4. Chemical Manufacturing

Quicklime is a fundamental component in the production of various chemicals. It is used in the manufacturing of calcium carbide, which in turn is used to produce acetylene gas. Quicklime is also employed in the production of calcium hypochlorite, a key ingredient in bleach and disinfectants.

5. Agriculture

In agriculture, quicklime is used to amend acidic soils. By raising the pH of the soil, quicklime improves soil structure and fertility, enhancing crop yields. It is also used in the treatment of animal waste and as a disinfectant in livestock housing.

Benefits of Quicklime

1. Cost-Effective

Quicklime is relatively inexpensive and widely available, making it a cost-effective solution for a variety of industrial and environmental applications. Its affordability and effectiveness make it a preferred choice for many industries.

2. Versatility

The versatility of quicklime is one of its greatest advantages. From construction to chemical manufacturing, quicklime can be used in a multitude of processes and products. This versatility ensures its continued demand across various sectors.

3. Efficiency

Quicklime is highly efficient in its applications. For instance, in wastewater treatment, a small amount of quicklime can neutralize large volumes of acidic waste, making the process both efficient and economical. Its reactivity and effectiveness ensure high performance in all its uses.

4. Environmental Benefits

Quicklime contributes to environmental sustainability in several ways. It aids in the treatment and neutralization of industrial waste, reducing the environmental impact of hazardous substances. In agriculture, it promotes healthy soil and plant growth, leading to more sustainable farming practices.

Production of Quicklime

The production of quicklime involves several steps, starting with the extraction of limestone from quarries. The limestone is then crushed and sorted before being subjected to the calcination process. Here is a detailed overview of the production process:

1. Extraction and Crushing

Limestone, the primary raw material for quicklime production, is extracted from quarries through blasting or mechanical means. The extracted limestone is then transported to a crushing facility, where it is reduced to smaller, more manageable pieces.

2. Calcination

The crushed limestone is fed into a kiln, where it is heated to temperatures above 825°C. This process, known as calcination, causes the limestone to decompose into calcium oxide (quicklime) and carbon dioxide. The type of kiln used can vary, with rotary kilns and vertical shaft kilns being the most common.

3. Cooling and Storage

After calcination, the quicklime is cooled using air or water. It is then stored in silos or other appropriate storage facilities to protect it from moisture and contamination. Proper storage is essential to maintain the quality and reactivity of the quicklime.

4. Quality Control

Throughout the production process, quality control measures are implemented to ensure the consistency and purity of the quicklime. This includes regular testing of the limestone and quicklime for chemical composition and physical properties.

Safety and Handling of Quicklime

Given its caustic nature, quicklime must be handled with care to prevent injury and ensure safe use. Here are some key safety considerations:

1. Protective Equipment

When handling quicklime, it is essential to wear appropriate protective equipment, including gloves, goggles, and respiratory protection. This helps to prevent skin and eye contact and inhalation of dust.

2. Storage Conditions

Quicklime should be stored in a dry, well-ventilated area away from moisture and incompatible materials. Proper storage conditions help to maintain the quality and reactivity of the quicklime.

3. Handling Procedures

During handling and transportation, quicklime should be kept in airtight containers to minimize exposure to air and moisture. Proper handling procedures help to prevent accidents and ensure the safe use of quicklime.