Cement is the cornerstone of modern construction, playing a crucial role in building structures that range from residential homes to towering skyscrapers. However, not all cement is created equal. Different types of cement are engineered to meet specific construction needs and environmental conditions. This blog post will delve into the various types of cement available and their distinct uses in construction, helping you choose the right cement for your next project.

1. Ordinary Portland Cement (OPC)

Ordinary Portland Cement (OPC) is the most commonly used type of cement in the world. It is ideal for general construction purposes, including residential buildings, bridges, and pavements.

Uses:

- General building construction

- Concrete pavements

- Precast concrete products

- Reinforced concrete structures

2. Portland Pozzolana Cement (PPC)

Portland Pozzolana Cement (PPC) is a blend of OPC and pozzolanic materials like fly ash, volcanic ash, or silica fumes. PPC is known for its enhanced durability and reduced environmental impact.

Uses:

- Marine structures

- Hydraulic structures

- Sewage works

- Mass concrete works like dams

3. Rapid Hardening Cement

Rapid Hardening Cement sets faster than OPC, achieving high strength in a shorter period. It is beneficial for projects requiring quick turnaround times.

Uses:

- Road repairs

- Pavement construction

- Pre-fabricated concrete construction

- Cold weather concreting

4. Sulfate Resisting Cement

Sulfate Resisting Cement is designed to withstand sulfate attacks, making it suitable for environments with high sulfate concentrations in the soil or groundwater.

Uses:

- Foundations

- Basements

- Coastal structures

- Sewage treatment plants

5. White Cement

White Cement is a specialized type of cement with a white color, achieved by using raw materials that are low in iron and manganese. It is primarily used for aesthetic purposes.

Uses:

- Architectural finishes

- Decorative concrete products

- Terrazzo flooring

- Precast curtain walls

6. Colored Cement

Colored Cement is produced by adding pigments to OPC. It provides an aesthetic appeal and is used where the color of the concrete is a key design feature.

Uses:

- Decorative flooring

- Exterior walls

- Pathways

- Sculptures

7. Low Heat Cement

Low Heat Cement generates less heat during the hydration process, making it suitable for massive concrete structures where heat generation could cause cracking.

Uses:

- Large dams

- Massive foundations

- Large retaining walls

- Bridge piers

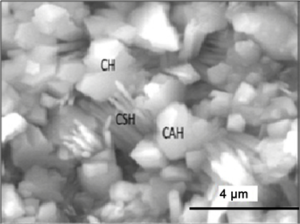

8. High Alumina Cement

High Alumina Cement is made from bauxite and limestone and has high compressive strength and rapid setting properties. It is resistant to chemical attacks and extreme temperatures.

Uses:

- Refractory concrete

- Chemical plants

- Sewer infrastructure

- Underwater construction

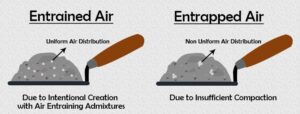

9. Air-Entraining Cement

Air-Entraining Cement contains agents that introduce tiny air bubbles into the concrete mix, improving its workability and resistance to freeze-thaw cycles.

Uses:

- Pavements and highways

- Bridge decks

- Airport runways

- Exposed concrete structures in cold climates

10. Expansive Cement

Expansive Cement expands slightly after setting, counteracting the shrinkage that can occur during drying and reducing the likelihood of cracks.

Uses:

- Grouting anchor bolts and machine bases

- Repair of concrete structures

- Pre-stressed concrete

Selecting the appropriate type of cement is crucial for the longevity and performance of a construction project. By understanding the unique properties and uses of each type, you can ensure that your structure not only meets its functional requirements but also withstands environmental challenges. Whether you are building a simple residential home or a complex infrastructure project, the right cement can make all the difference.

For more information on construction materials and tips, stay tuned to our blog section. If you have any questions or need advice on choosing the right cement for your project, feel free to contact us!